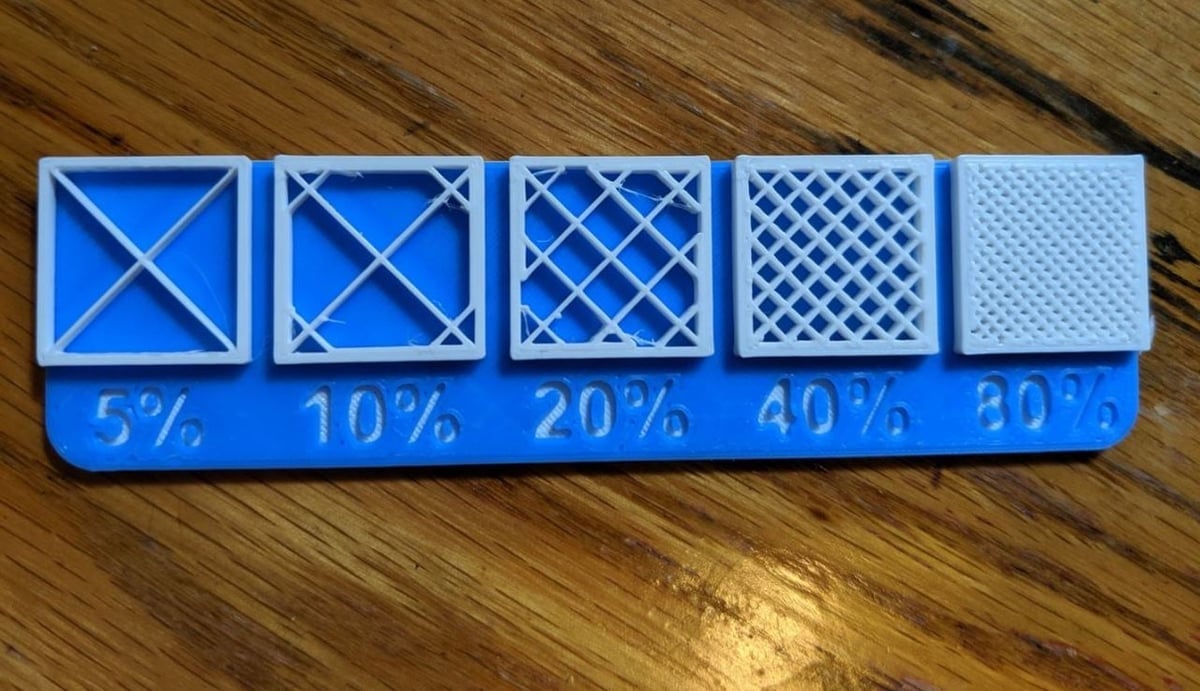

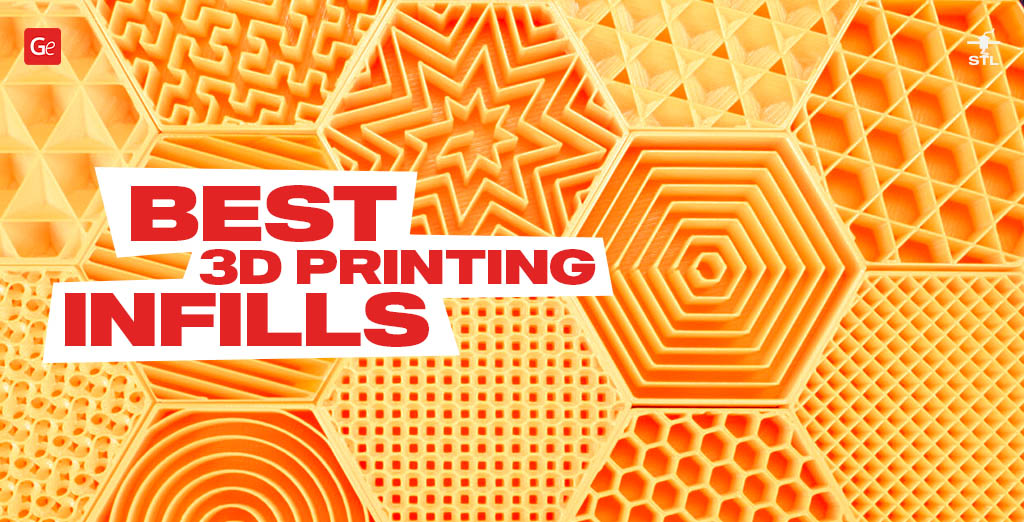

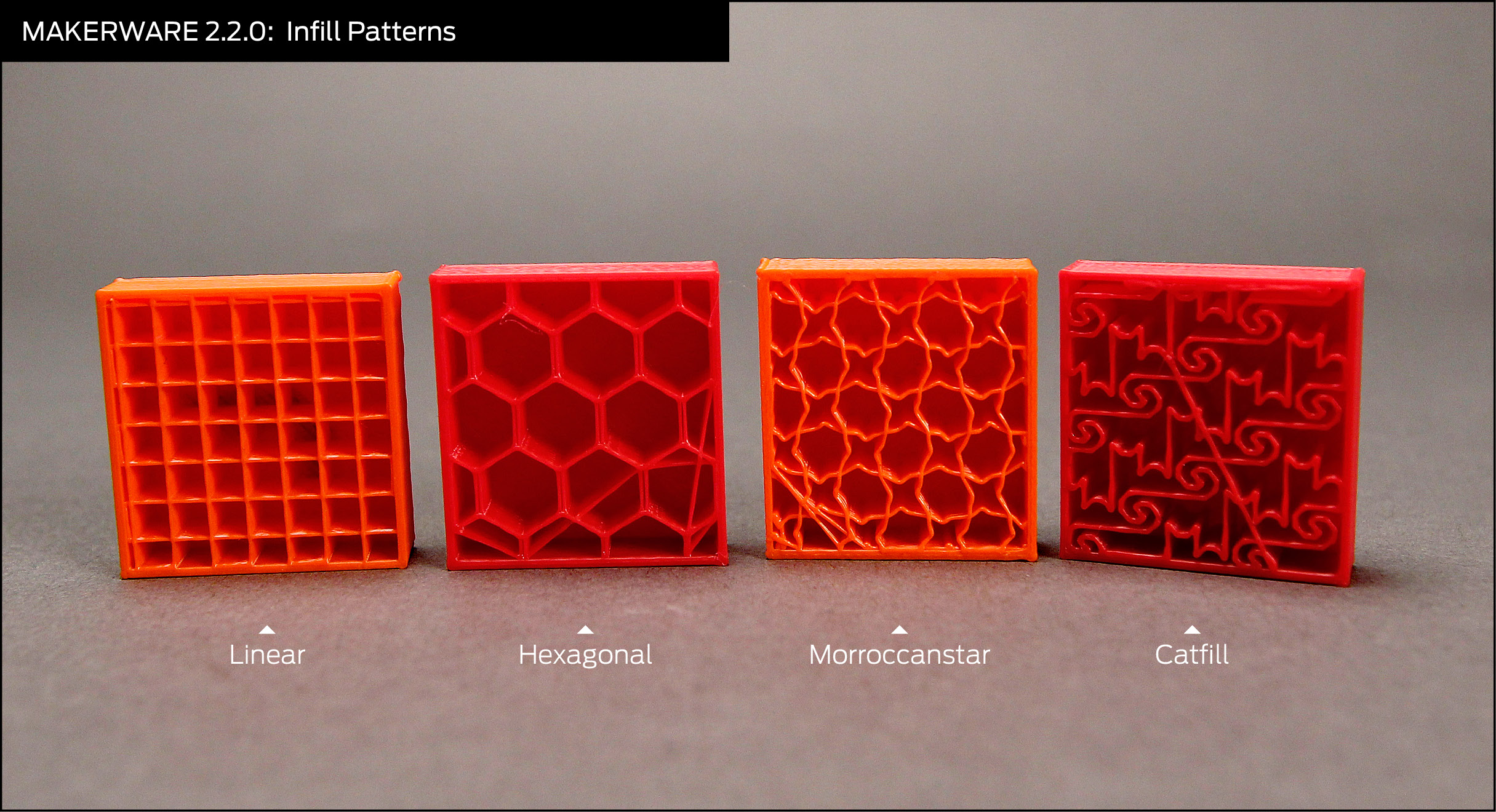

Effect of Filling Pattern on the Tensile and Flexural Mechanical Properties of FDM 3D Printed Products | SpringerLink

ANYCUBIC 3D Printer Photon M3 Max With Auto Resin Filling 13.6 Inch 7K Monochrome Screen Larger 298*164*300mm Resin 3d Printers _ - AliExpress Mobile

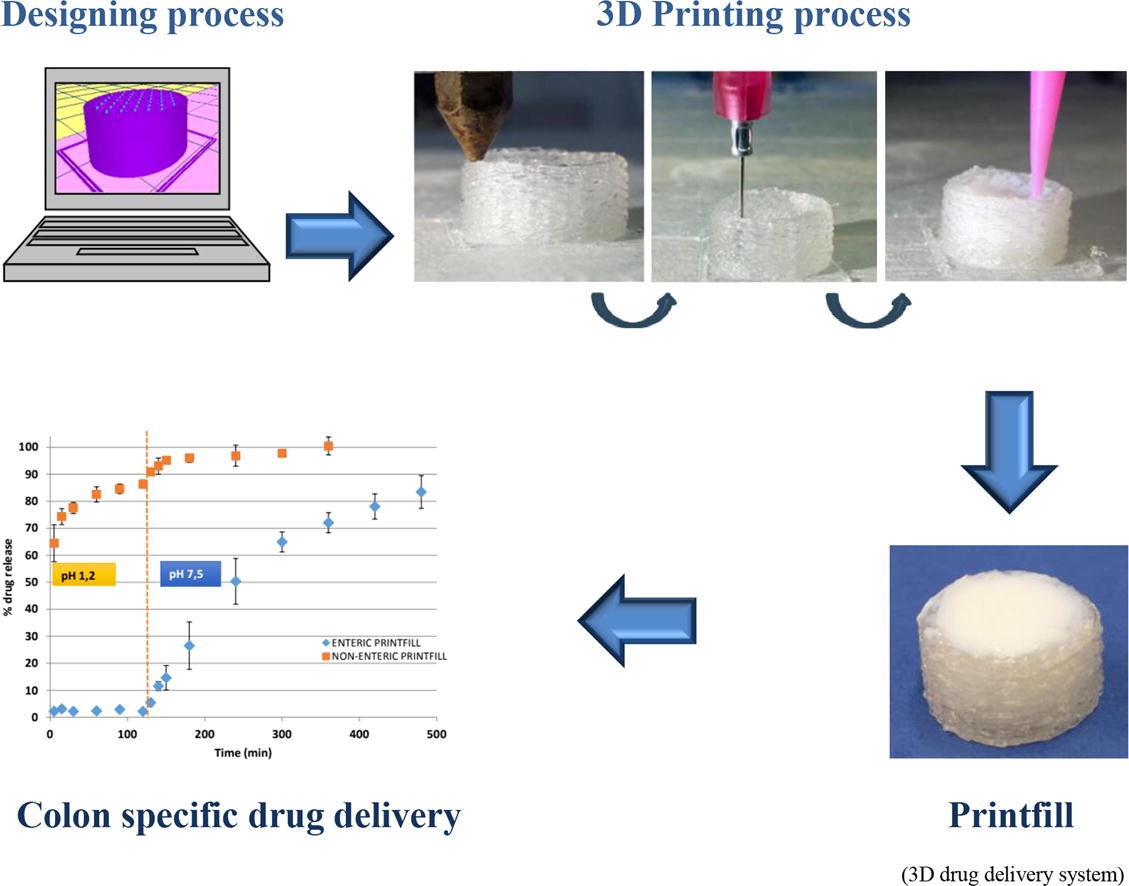

Printfills: 3D printed systems combining Fused Deposition Modeling and Injection Volume Filling. Application to colon-specific drug delivery - Pharma Excipients

Liquefied Filament Fabrication PLA/ABS/Metal -Fill/Wood Desktop 3D Printer Pratham 1.0, Model Name/Number:

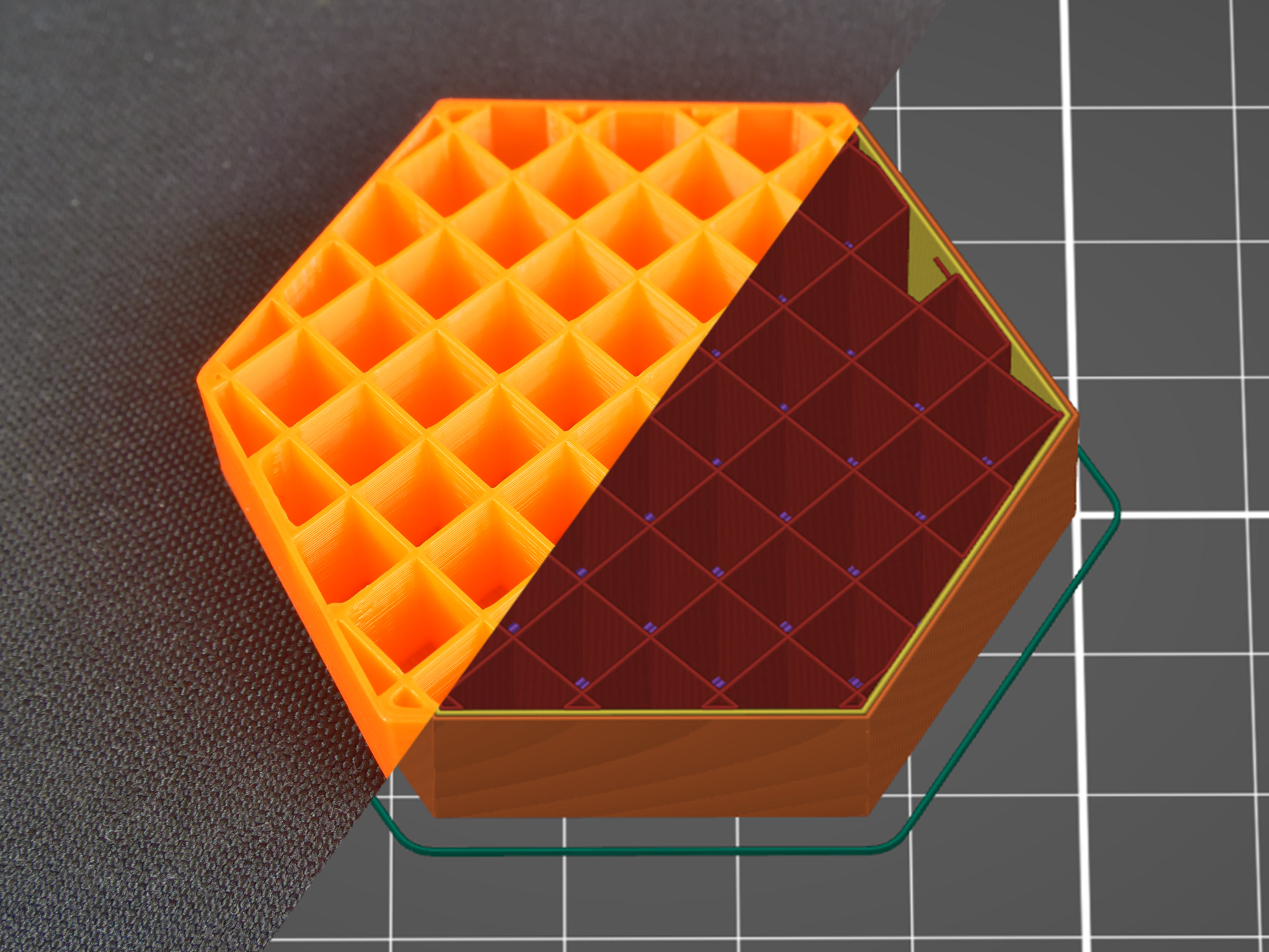

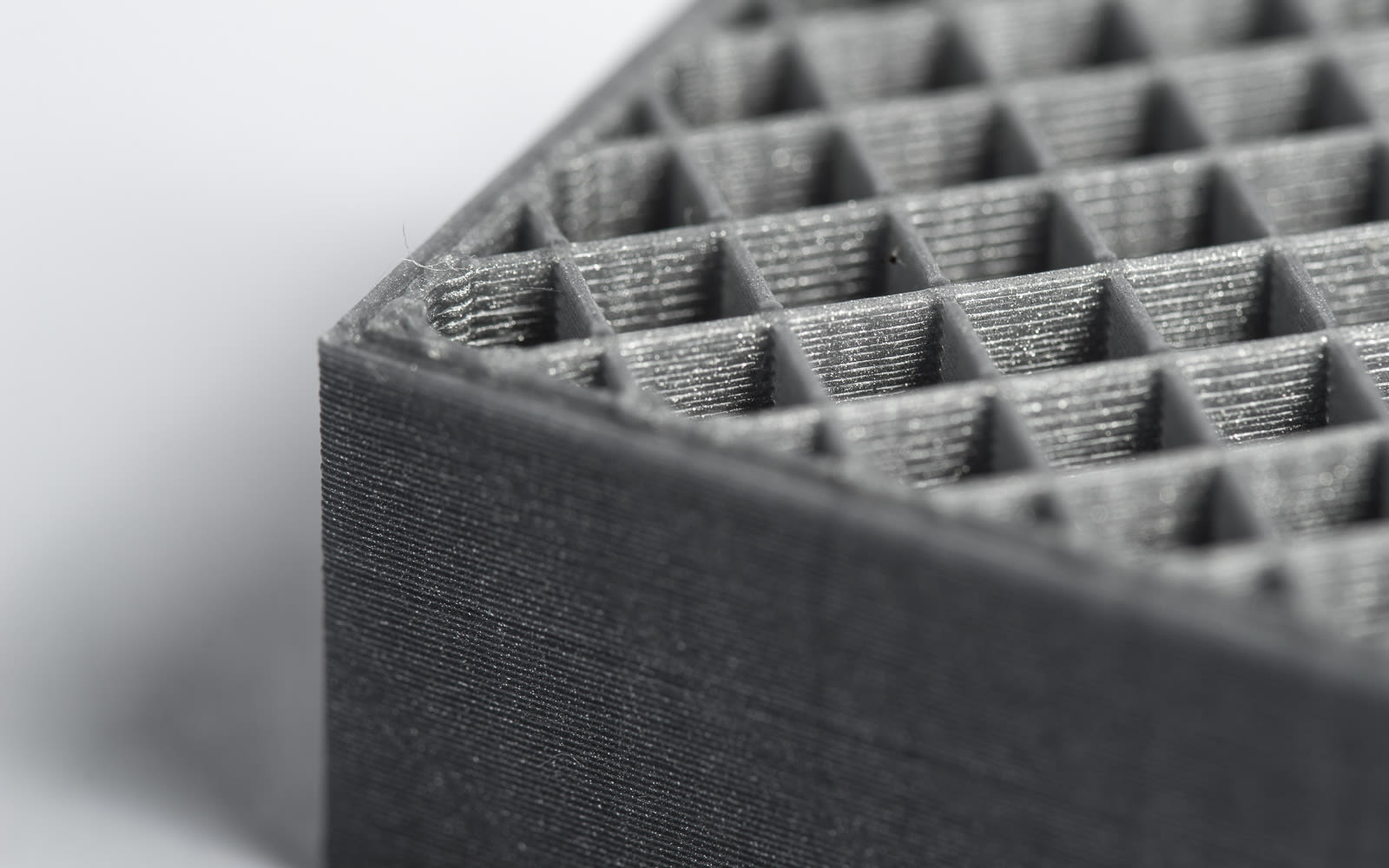

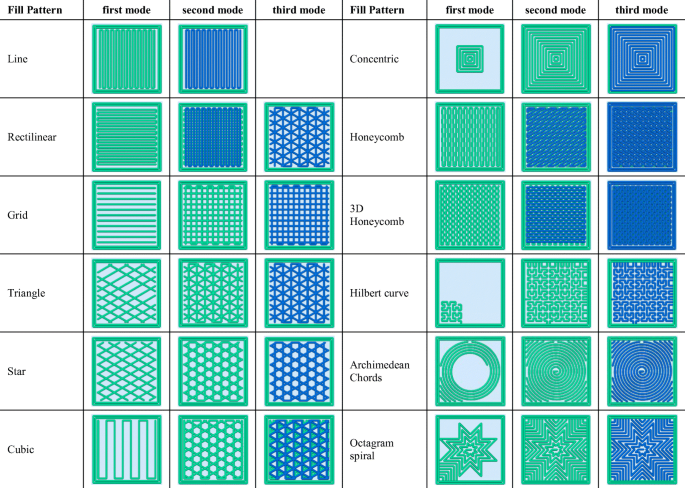

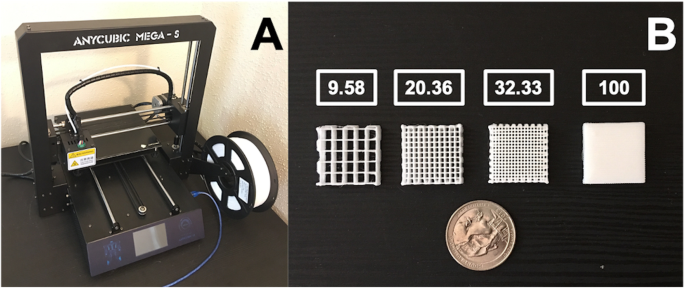

Understanding the relationship between slicing and measured fill density in material extrusion 3D printing towards precision porosity constructs for biomedical and pharmaceutical applications | 3D Printing in Medicine | Full Text

Pharmaceutical 3D printing: Design and qualification of a single step print and fill capsule - ScienceDirect